As industries evolve and production demands increase, businesses seek more efficient, accurate, and reliable measurement tools. In this space, a battle between coordinate measuring machines (CMMs) and air gages arises. Both methods deliver highly precise results, but they are suited to different applications and environments.

We’ll compare these two solutions and consider their features and benefits. This information will help business owners make an informed decision about which measurement technology best suits their needs.

Key Differences Between CMMs and Air Gages

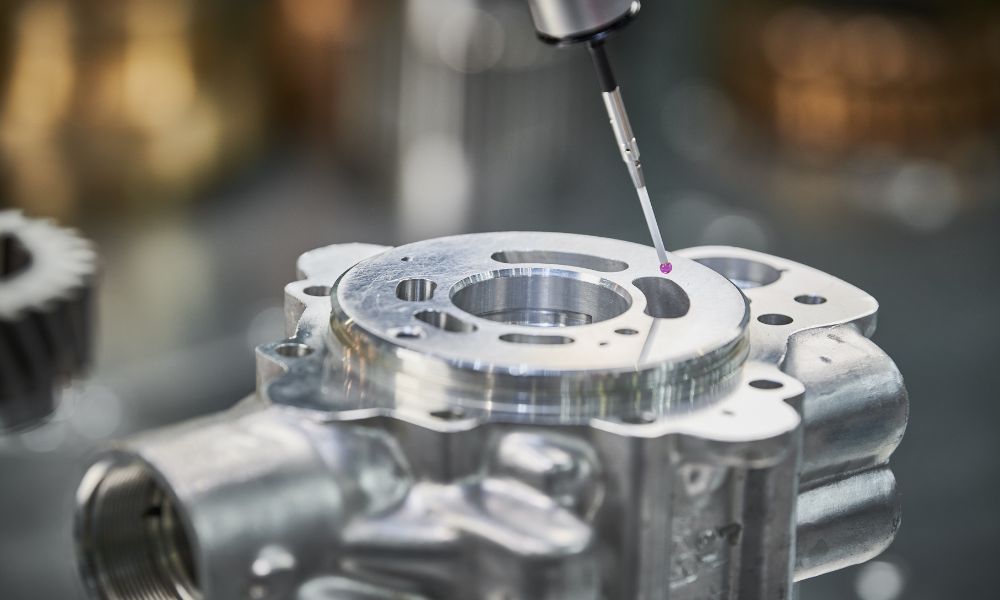

A coordinate measuring machine uses a probe to measure the dimensions and tolerances of a part, providing detailed 3D measurements. These machines are best suited for large-scale production environments and can handle highly complex parts. CMMs are typically computer-controlled and demand extensive operator training and technical expertise to program and operate effectively.

Air gages rely on airflow to measure precisely. Air-gaging products use regulated airflow through precision vents to create a back pressure that corresponds with a dimensional feature of a part. While CMMs provide 3D measurements, air gages focus on tighter tolerances on dimensions like diameter, width, and thickness.

Notable Advantages of Using Air Gages

One thing that makes the comparison between coordinate measuring machines and air gages unfair is the industry preference for CMMs. Let’s look deeper at the key benefits of choosing air gages.

Ease of Use

Air gages are designed with the non-expert in mind, making them more accessible for users. Operators can collect measurements easily with minimal training, reducing the risk of human error.

Cost-Effectiveness

Air gages are significantly less expensive than CMMs and have lower operating and maintenance costs. This affordable solution can provide exceptional value to businesses that need reliable dimensional measurements.

Speed and Efficiency

Air gaging systems deliver fast, real-time measurements, making them well-suited to the demands of high-volume manufacturing environments.

Precision

Air gages can measure tight tolerances with remarkable accuracy and repeatability, providing manufacturers with a high level of quality control and assurance.

Choosing the Best Solution

When deciding between these two options, consider the specific requirements of your production environment. Businesses that require 3D measurements and handle highly complex parts should invest in a CMM. However, air gaging products are more advantageous for businesses focusing on high-volume manufacturing and requiring a cost-effective solution for reliable and efficient dimensional measurements.

Various industries require precise and efficient measurement tools, so understanding the differences between CMMs and air gages empowers businesses to boost productivity and ensure high-quality standards within their fields. By carefully considering the unique demands of your environment, you can choose the best measurement technology for your business.